Table of Contents

Ramp with a constant slope

Block name

B84_SLEW_RATE_LIMIT

ST call

PROGRAM TEST B84 VAR REAL1,REAL2 : REAL; FB : LIB.CORE.V1_0.B84_SLEW_RATE_LIMIT; END_VAR FB(IN:=REAL1, TDOWN:=2000 ,TUP:=2000,OUT=>REAL2); END_PROGRAM

Library

LIB\CORE

Version

V1.0

Description

The block prevents the signal from rapid changes, the maximum slew rate is defined by the tup and tdown times which define the time for the signal to change from 0 to 100 and back. There are separate parameters for signal rising and falling.

Inputs

| Input | Type | Description | Default value |

| IN | REAL | Input signal | 0 |

| TDOWN | TIME | Falling time for change from 100 to 0, in ms. | 30s |

| TUP | TIME | Rising time for change from 0 to 100, in ms | 30s |

Outputs

| Output | Type | Description |

| OUT | REAL | Processed output signal |

| SIGN | BOOL | Sign of the output signal |

Function

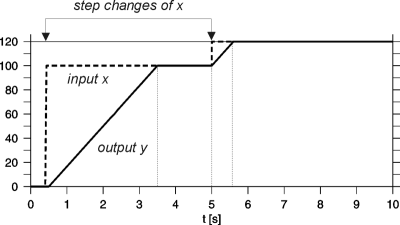

The block converts the input in to output out and limits the maximum velocity of change of the output signal out. The slope is defined by parameters Tdown and Tup, separately for rising and falling signal. Tdown is time necessary for change of y from 100 to 0, while Tup is travel time from 0 to 100. When the input in is changing its value more slowly than this, then out=in, otherwise the output follows the input with maximum speed of change defined by Tdown and Tup.

If Tdown=0 then the falling signal is copied to the output immediately. If Tup=0 then the rising signal is copied to the output immediately. At program start, the input in is copied to the output.

The output sign indicates the sign of the output signal out. If y>= 0 then sign=true, otherwise sign=false.

Function in case of wrong setting

If Tdown⇐ 0 then Tdown=0, if Tup⇐ 0 then Tup=0.

Figure 1: B84 Situation for Tup=3s. The slew rate is const.

Application example

The block is used for slow opening of valves at steam heat exchangers. The falling time is 0 so that the valve shuts down immediatelly according to the PI controller, while the rising time may be several minutes for the valve to open slowly even if the controller gives fast output response. This is to prevent rapid changes of pressure and temperature in the exchanger piping.