Access to variables of another PLC

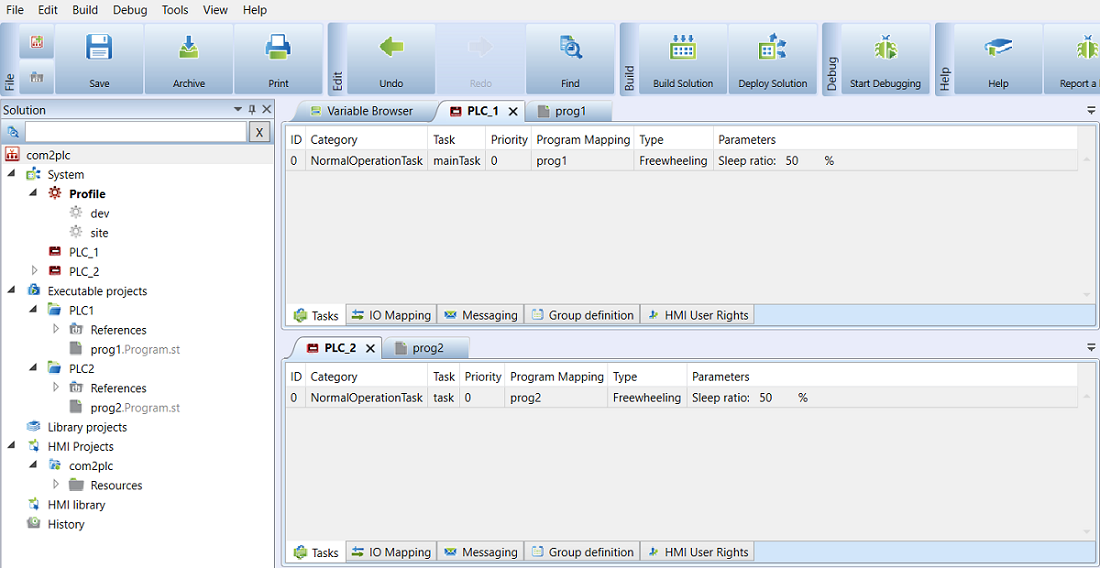

Create a Solution with more PLCs. In this example, two PLCs will be used; the principle is the same with 3 and more PLCs. Each PLC shall have a separate project with one program.

Both PLCs shall contain a simple program which uses a variable which will be changed manually. Another variable will read a value from the other PLC.

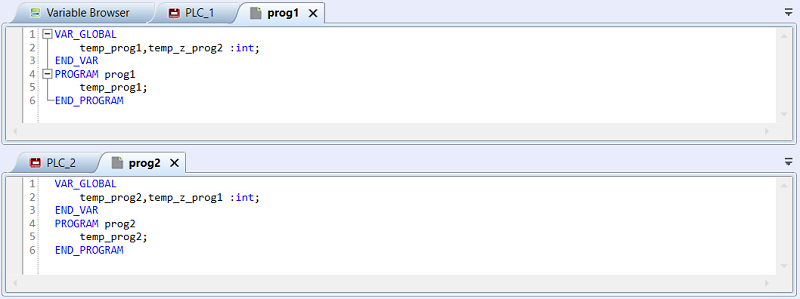

Insert a channel in both PLCs, and configure it according to the next figure. Change the timeout and pause between telegrams if necessary.

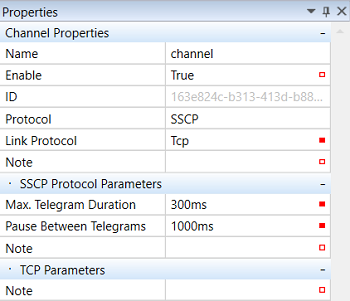

Add a device to the channel. In the device properties, set source PLC, SSCP address, access name and password.

Endpoint:

HwConfiguration - the IP address which is set up in the HW configuration of the selected PLC will be used.

Deploy - use the IP address to connect to the PLC.

Custom - IP address used in this communication device properties will be used.

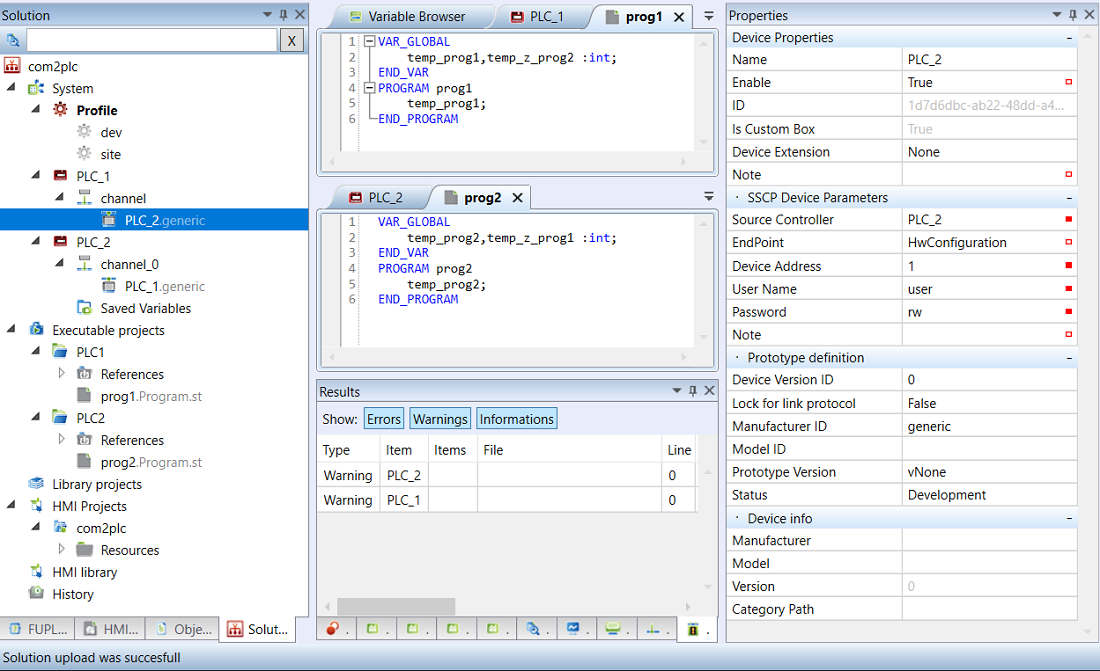

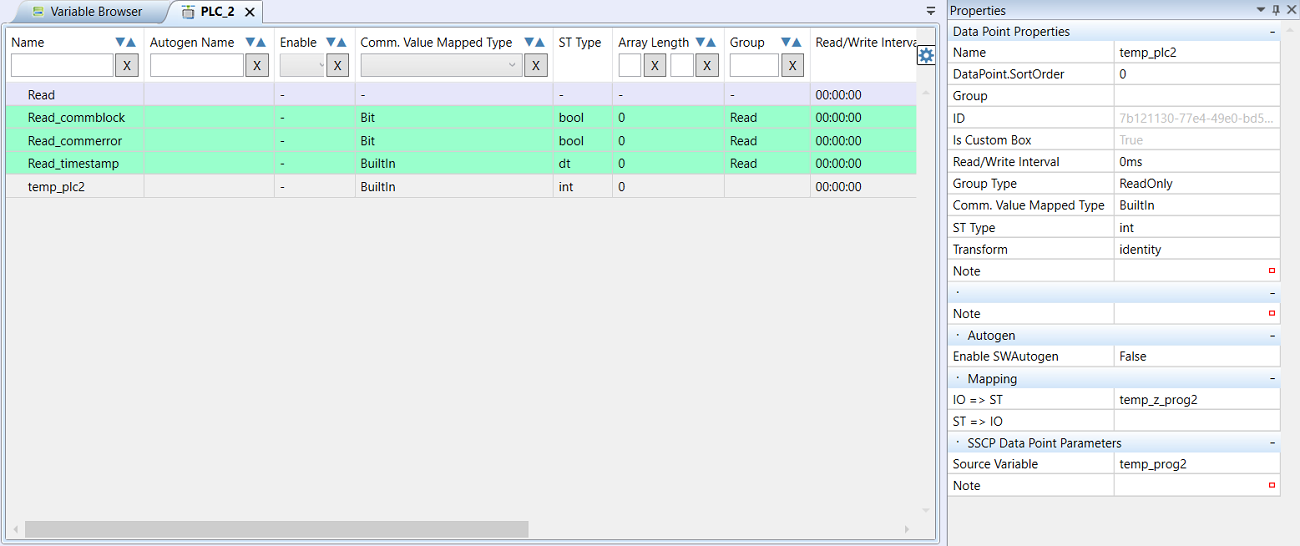

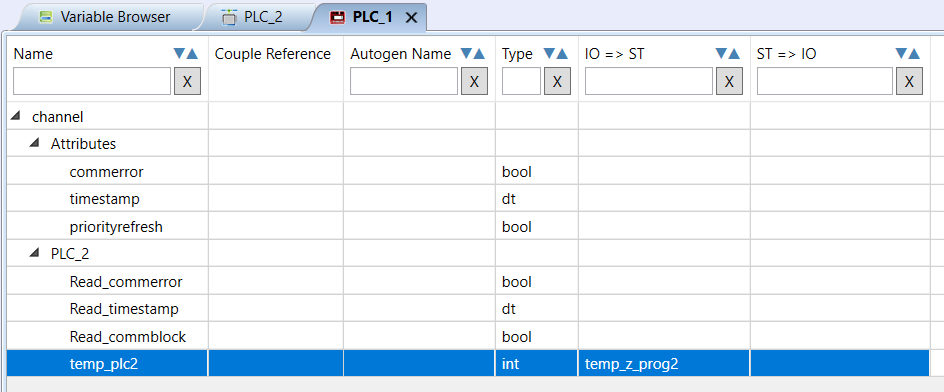

Add a group to be used to read data. For every variable we want to see in the other PLC, insert a hardware variable. Set up the variable type and in the “Source variable” parameter select the variable to be read.

In variables mapping, attach the real variable in which the value will be displayed in the other PLC.

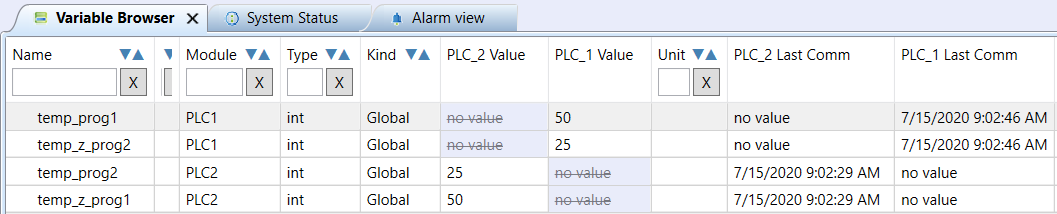

Compile and deploy the solution, run Debug at both PLCs. Every PLC will have its own column with values and last communication timestamp.